Sieve Bend Screen Working Process

Basic Info

Model No.: XL-FY643

Product Description

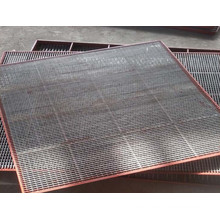

Model NO.: XL-FY643 Hole Shape: Square Wire Type: Triangular, Round, V Wire, Keystone, Wedge Wire Triangular Size Support Wire: 1.5X2,1.5X2.5,2X3.5,3X4.6,3X5.5,3.5X5mm Trademark: XL(FY) Origin: Xinlu Wire Mesh, Anping County Material: Stainless Steel Wire Application: Liquid Filtration, Screening, Solid-Liquid Separation, Gas-Liquid Separation, Dry Filtration, Dustproof, Gas Filtration Triangular Size Profile Wire: 1.5X2,1.5X2.5,2X3.5,3X4.6,3X5.5,3.5X5mm Support Bar: 1.5X20,1.8X10,2.0X10,3.0X10,2X25mm,2.5X30mm Specification: to order HS Code: 73144900 Sieve Bend Screen Working Process

Sieve bends screen production processing:

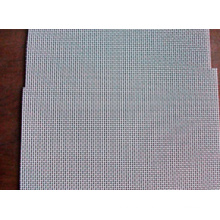

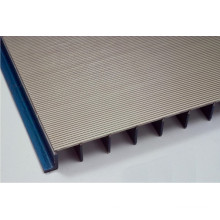

The Sieve Bend Screen comprises a concave static screen manufactured from non-blinding stainless steel wedge wire, with screen apertures oriented perpendicular to the direction of flow.

The wedge wire offers superlative filtering abilities with a precision-engineered structure that is non-clogging. It's flexible and can be supplied in a range of sizes and profiles. The screen surface can be supplied in 304 or 316 stainless steel. A polyurethane option is also offered.

Screen apertures between 0.35mm and 5mm may be provided in different profiles for specific applications. Key considerations influencing screen selection include:

Particle size cut point.

Feed rate.

Solids concentration.

Maximum particle size or size distribution.

The Sieve Bend frame is manufactured from mild steel but can be custom-made in other materials such as stainless steel or carbon steel if required.

How sieve bend screen work?

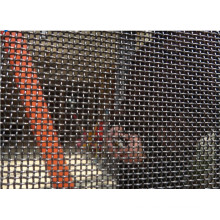

Solids-bearing liquid (or slurry) is poured into the feed box and overflows onto the screen. The sharp, leading edge of each wedge wire slices away a thin layer of water and small-particle solids.

Larger particles continue down the screen surface until most of the liquid is removed. The size of particles separated is determined by the size of the coal particles and their settling velocity in the liquid.

Separation size, in most operations, is usually about half the size of the screen aperture. Contact us if you need more details on Wire Wrapped Flat Panel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flat Wedge Wire Panel、Wedge Wire Curved Screens. If these products fail to match your need, please contact us and we would like to provide relevant information.

Sieve bends screen production processing:

The Sieve Bend Screen comprises a concave static screen manufactured from non-blinding stainless steel wedge wire, with screen apertures oriented perpendicular to the direction of flow.

The wedge wire offers superlative filtering abilities with a precision-engineered structure that is non-clogging. It's flexible and can be supplied in a range of sizes and profiles. The screen surface can be supplied in 304 or 316 stainless steel. A polyurethane option is also offered.

Screen apertures between 0.35mm and 5mm may be provided in different profiles for specific applications. Key considerations influencing screen selection include:

Particle size cut point.

Feed rate.

Solids concentration.

Maximum particle size or size distribution.

The Sieve Bend frame is manufactured from mild steel but can be custom-made in other materials such as stainless steel or carbon steel if required.

How sieve bend screen work?

Solids-bearing liquid (or slurry) is poured into the feed box and overflows onto the screen. The sharp, leading edge of each wedge wire slices away a thin layer of water and small-particle solids.

Larger particles continue down the screen surface until most of the liquid is removed. The size of particles separated is determined by the size of the coal particles and their settling velocity in the liquid.

Separation size, in most operations, is usually about half the size of the screen aperture. Contact us if you need more details on Wire Wrapped Flat Panel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flat Wedge Wire Panel、Wedge Wire Curved Screens. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Johnson Screen Plate

Premium Related Products

Other Products

Hot Products

Hot Dipped Galvanized Razor Wire for shield ---- 30 years factoryvarious of material Earphone Current Collector in weave type / expanded type / perforated type ----- 30 years factoryhot sale 0.05-8mm wire diameter pure silver wire(30 years factory)anping gold wire meshwrapped edge 99.95% tungsten wire meshmolybdenum wire woven meshhot dip galvanized PVC coated wire mesh fencetwist galvanized concrete wire meshrectangle hole welded pet cage wire meshAluminum Woven Wire Meshcopper wire meshPlatinum Expanded Anode Meshfine nickel wire meshCBRL anping KAIAN titanium mesh used in strong acid/alkali/environmental/chemical industry(30 years factory)Varoius of Stainless Steel Wire Mesh ---- 30 years factorypure silver woven wire mesh